The Benefits of Fluid Air Bed Roasting for Coffee

Share

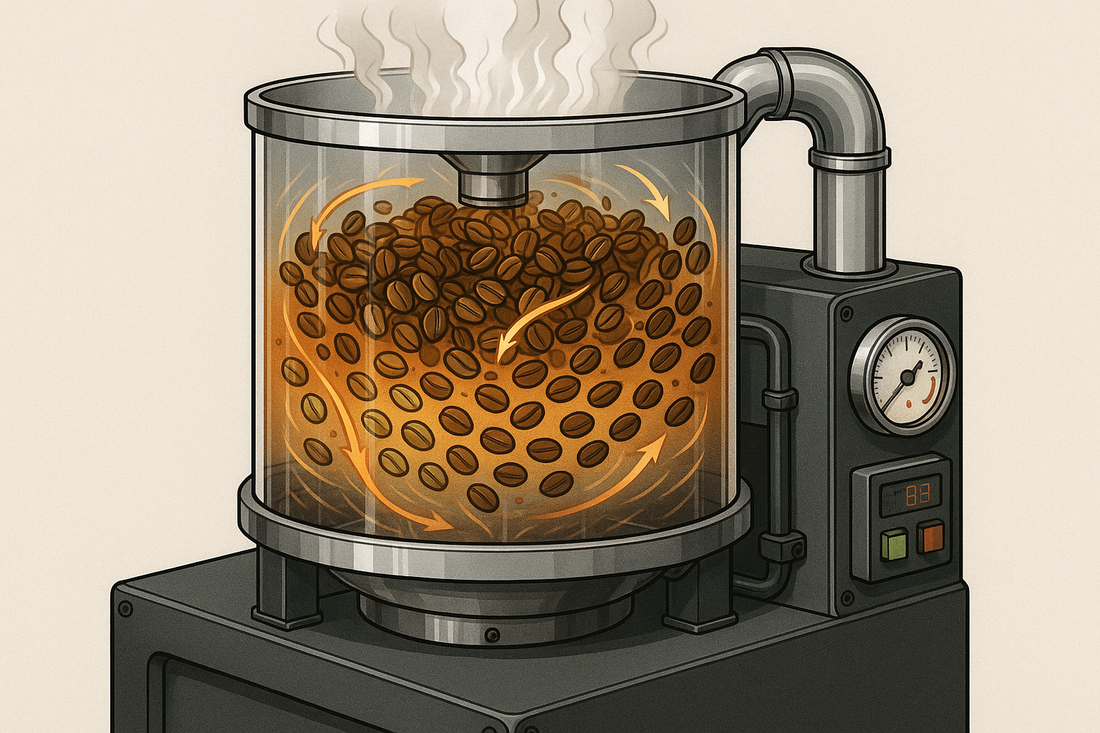

When most people think of coffee roasting, they picture a steel drum spinning over a flame, beans tumbling around until they turn brown and aromatic. That’s drum roasting — the centuries-old workhorse of the coffee industry. But there’s another method gaining traction among specialty roasters: fluid air bed roasting, sometimes called fluid bed roasting or hot air roasting.

In this system, the beans float on a rising column of hot air, almost like they’re “dancing” in a popcorn popper. Instead of relying on a heated metal drum to transfer heat, the roast is powered primarily by convective heat transfer — the movement of hot air around each bean.

Here’s why fluid air bed roasting is worth your attention.

1. Exceptional Heat Control

In a drum roaster, heat reaches beans in three ways: conduction (bean touching hot metal), convection (air movement), and a little radiation (heat from the roaster walls). In a fluid bed, conduction is almost zero — nearly all the heat is convective.

Why this matters:

• Rapid response: Changing temperature or airflow can instantly adjust the roast curve.

• Even development: Beans roast uniformly, without “tipping” or scorching from hot metal surfaces.

• Consistent batch-to-batch results: Less risk of one side of the bean roasting faster than the other.

2. Cleaner Flavor Profiles

Because the beans are suspended in moving air, chaff (the thin skin that flakes off during roasting) is blown away continuously. In drum roasting, chaff can collect in the drum and burn, contributing smoky or ashy undertones to the coffee.

Fluid bed benefits:

• Cleaner cup clarity — especially for bright, high-acidity coffees.

• Better representation of origin character — floral and fruity notes pop without being masked by roastiness.

• Reduced bitterness — especially at lighter roast levels.

3. Faster Roast Times

Hot air is an incredibly efficient heat transfer medium when applied correctly. Fluid bed roasters can reach target roast levels more quickly than drum roasters — often in 6–10 minutes for a medium roast versus 10–15 minutes in a drum.

Advantages of shorter roast times:

• Preserves delicate aromatics like jasmine, bergamot, or berry.

• Allows for high-throughput roasting without sacrificing quality.

• Reduces risk of “baked” flavors from overly long roast cycles.

4. Gentle on the Beans

Fluid beds keep beans moving constantly without heavy mechanical agitation. That means:

• No risk of chipping or cracking from paddles or drum vanes.

• Less friction and wear on the bean surface.

• Consistent physical development with minimal defects.

This gentle handling also makes fluid bed roasting particularly attractive for fragile microlots or coffees with low moisture content.

5. Environmentally Friendly & Cleaner Operation

Because hot air is both the roasting medium and the chaff removal mechanism, fluid bed roasters:

• Require less mechanical complexity (fewer moving metal parts to heat).

• Separate and collect chaff automatically, making post-roast cleanup easier.

• Often use electric heat sources, which can reduce emissions when paired with renewable power.

Many modern fluid bed roasters also have integrated afterburners or filtration systems that reduce smoke output, making them more suitable for small spaces and urban settings.

The Takeaway

Fluid air bed roasting isn’t “better” than drum roasting in every context — but it offers real advantages for certain coffees and certain roasters. If your goal is maximum clarity, repeatability, and a bright, clean flavor profile, this method deserves serious consideration.

In a world where coffee is increasingly valued for its origin expression and nuanced flavor, fluid bed roasting is not just a technological curiosity — it’s a tool that can help unlock the full potential of the bean.